An innovative drone-based inspection system using a custom-balanced telephoto lens setup on a DJI Inspire 1 enables safer, more cost-effective structural assessments of towers and smokestacks compared to traditional cherry picker approaches.

In 2016, while most drone operators were busy taking aerial selfies, I was solving a rather unique engineering challenge: how to get detailed structural photos of towers without turning an expensive drone into a very dramatic firework display.

Inspecting weather damage due to freeze/thaw cycles in tower structure

Communication towers require quality control assessment post RF installations

The problem started when architecture firms approached me about using drones for structural inspections of smokestacks and radio towers. These century-old brick and mortar structures, while mostly inactive today, still require regular maintenance to prevent their gradual descent into rubble. Traditionally, firms would dispatch teams with cherry pickers – essentially extremely expensive selfie sticks – to photograph and inspect these structures up close.

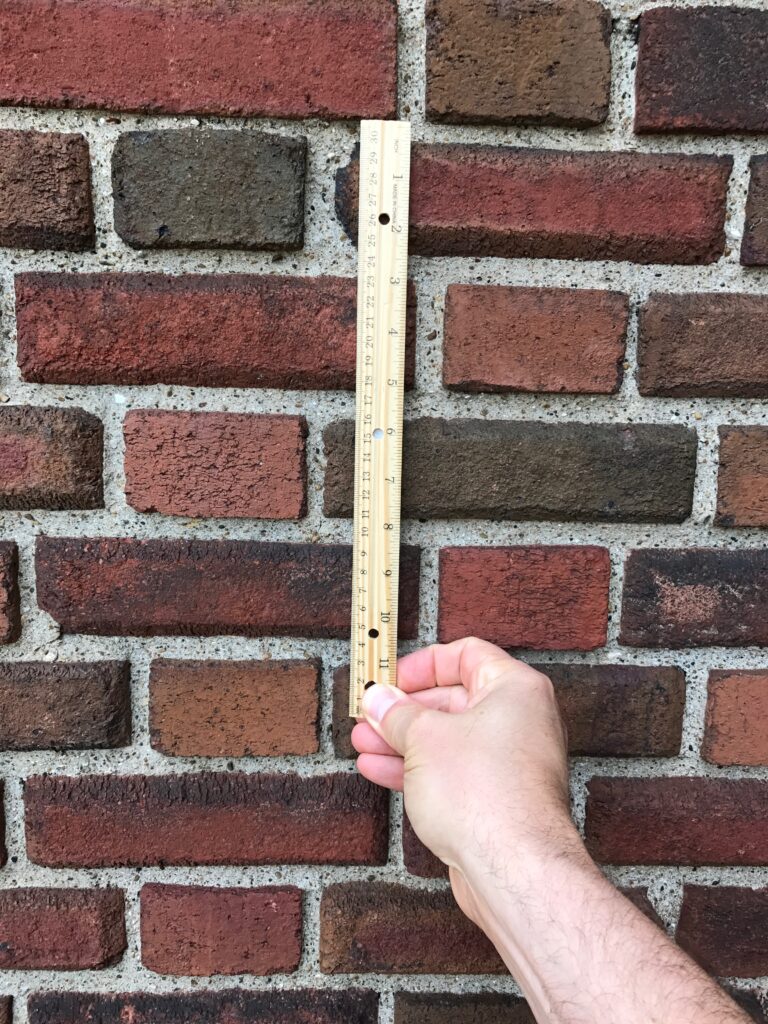

Providing architecture firm with in-situ measurements for scale extrapolation

The Technical Challenge

The DJI Zenmuse gimbal stabilized micro 4/3″ camera system for the Inspire 1

The standard approach of flying a drone near these structures posed significant risks. Getting close enough for detailed shots meant putting expensive equipment (and potentially people) at risk. The solution? Transform a DJI Inspire 1 drone into a flying telephoto platform.

The heart of the system was the DJI Inspire 1’s Zenmuse camera with its four-thirds-inch sensor. I paired this with an Olympus zoom lens that provided approximately 200mm equivalent focal length – enough reach to spot a squirrel’s retirement nest from a safe distance. However, this created a new problem: the extended lens would overload the gimbal motors when zooming, threatening to turn our precise imaging platform into a very expensive pendulum.

Custom Engineering Solutions

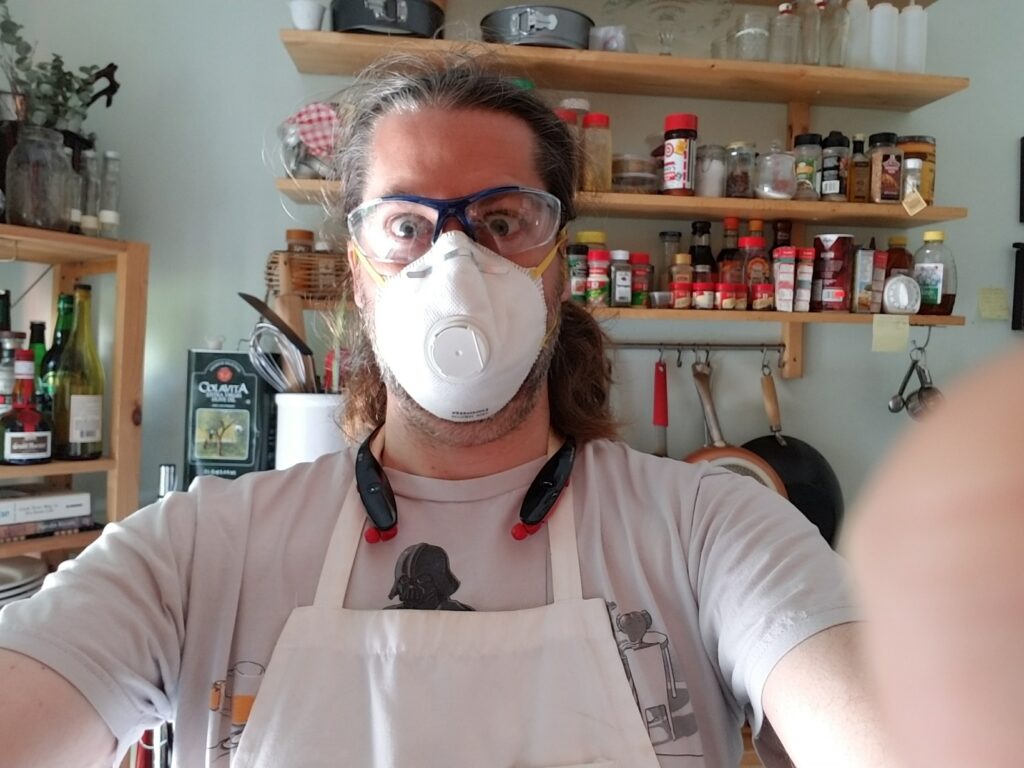

Melting lead fish weights for a custom counterbalance for the new telephoto lens

The solution involved some rather unusual drone modification: custom lead counterweights. By melting down fishing weights and crafting a precisely balanced counterweight system, I could offset the lens’s forward weight. This required careful iteration – removing unnecessary lens components like the original hood (replaced with a lightweight paper tape version) and fine-tuning the counterweight by gradually shaving off lead until achieving perfect balance.

The resulting system could maintain stable flight while capturing incredibly detailed images from a safe distance. We could inspect radio equipment installations, examine structural integrity issues, and even spot wildlife residents without disturbing them (or risking becoming part of their home improvement projects).

Workflow and Image Processing

Inspecting smoke stack tops for 5G antenna installation structural integrity assessment

Our inspection protocol involved:

- Establishing a safe flight perimeter

- Conducting circular flight patterns around the structure

- Capturing approximately 100 high-resolution images per inspection

- Implementing color management techniques to enhance shadow detail and correct exposure issues

- Organizing data with unique geolocation identifiers

- Uploading to cloud storage with our custom workflow system

Scaling Challenges

Scaling this operation across Michigan, Wisconsin, and New York revealed an unexpected truth: finding someone who can simultaneously pilot a drone, take professional-quality photographs, handle complex equipment modifications, and navigate FAA regulations is about as rare as finding a smokestack without pigeons.

The ideal operator needed:

- FAA licensing and understanding of NOTAM procedures

- $2 million in liability insurance

- Expertise in drone piloting in urban environments

- Professional photography skills

- Technical ability to handle custom equipment

- Data management capabilities

- The judgment to operate safely around schools and public facilities

Cost-Benefit Analysis

The economics made sense: traditional inspections could cost upwards of $1,000 just for cherry picker rental, not counting the crew and time involved. Our drone-based approach could complete an initial assessment in about 10 minutes, providing enough detail for engineers to determine if a full physical inspection was warranted. This preliminary screening alone could save thousands in unnecessary full inspections.

Regulatory Considerations

Operating in 2016 meant navigating a complex regulatory landscape. Each flight required:

- Airspace classification verification

- Facility authorization when near sensitive areas

- NOTAM issuance when required

- Special liability insurance coverage

- Coordination with local authorities

Conclusion

While we eventually moved on to other ventures (like Quantifly and parking analysis), this project demonstrated how drone technology could revolutionize traditional inspection methods. The combination of custom engineering, aviation skill, and photography expertise created a solution that was safer, more efficient, and more cost-effective than traditional methods.

And perhaps most importantly, we proved that sometimes the best way to inspect a structure isn’t by getting close to it – it’s by giving it some space and bringing along a really good zoom lens. After all, architecture is a lot like photography: it’s all about perspective.